Browsing Category : RV-10

Whelp, that sucks.

So during my condition inspection I made a bad decision. I used a block of wood in between my wing jack and my wing, and that block did not match the shape of the jack stand. Lowering the jack the block rotated and flipped out putting two small dents in the bottom of my wing. Fuck me. My fault, dumb…

A little wheel pant bling!

A big day is coming up on April 11th, I’ll be heading to Hibbing, Minnesota to drop off N241VP at Midwest Aircraft Refinishing. Before painting I had one last little project I wanted to get completed. Flyboy Accessories manufactures a high quality, stainless steel tow bar/tug guard for the nose wheel. I picked it up a few months ago and…

First Condition Inspection (Annual) of Van’s RV-10 N241VP – DONE

I customized my Condition Inspection checklist based on Walt’s (EXP Aircraft Services LLC) checklist. I also added some frequently needed documents/information to the end of my document. Here is a link to my checklist As with building, there was a learning curve this year that added a good amount of extra time and effort. Next year I think the Condition…

EAA Airventure 2021

I’ve attended Airventure a bunch of times. Always camping but sometimes driving and sometimes flying. I’ve experienced the mass arrival at KOSH, I’ve spent hours waiting to depart after the show, and experienced the nearly every year big storm. Well this year checked most of those boxes but the most important new one, flying a plane I built. Big shout…

What I learned from the Airventure 2021 forums

I sucked from the fire hose the engine information presented at Airventure this year. Mike Busch put on 13 seminars and I think I hit five or maybe it was six of them. I also took in a leaning seminar presented by Martin Pauly. And a great presentation by Vic Syracuse specific to amateur built aircraft (I was able to…

N241VP made it home!

Well I have been neglecting my blogging duties lately. But with the arrival of N241VP in Steamboat it was no longer reasonable to continue my laziness. But before getting to that, a recap on the last month… The phase 1 flight testing went overall quite smooth. I had some concerns about proper engine break-in which led to flying to SE…

Successful first flight

Holy Hannah what a day! I had not expected to make my first flight today because I wanted wind from the south since that would keep me flying on take off over empty fields until I reached a safe altitude. Winds were forecast from the north so I settled in to cleaning up a few small projects until Loyd arrived…

Success!

With four hours until the inspector arrived it was hustle time to knock off the last few items. First up was installing the lighting and Plexiglas in the right wing tip. After making a few passes on englarging the opening the landing and taxi lights slid right in and from there is was easy going. The wing root fairings were…

Big final push

My work day started at 4:00am and I put in 16 hours getting my plane ready for tomorrows inspection. And yes, I am exhausted. But I should be ready to go after a few hours checking the final items off the list. Today I finally got around to the louvers on the bottom cowling. This was a time consuming process…

Interior Clean Up

The day started off with making good time on the right wing tip access door. Everything fell into place and soon I had everything cleco’d together and flox between the fiberglass door and the metal stiffener curing. Then is was on to electrical stuff. I knocked out the prep wiring for the right wing tip light. So once the tip…

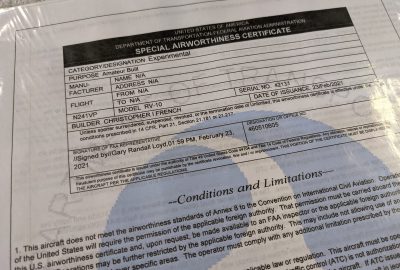

Add certification to N241VP

No not the Airworthiness, but rather certification of the transponder and static systems. This was a much more involved process than I expected. All told it took three and a half hours. A good chunk of that was fixing leaks. At every threaded fitting there was a leak. I had used teflon tape but the system still leaked. Could have…