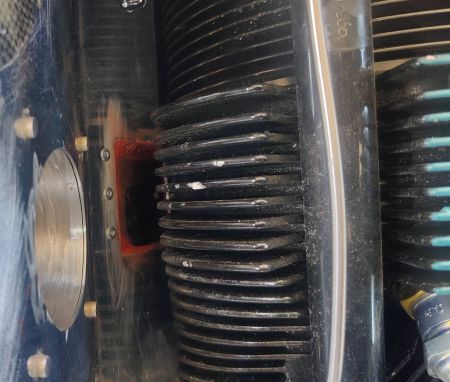

The back right cylinders on Lycoming engines are always the hottest on Van’s RV planes. I’ve not had any major issues (with CHT temperatures) on cylinder 5 until recently. Departing Las Vegas at 6:45am in 90+ degree temperatures it took a lot of playing with my climb rate and oil cooler dampener to keep the CHTs in line, and even then it was just over 400 degrees. That made me decided to circle back to posts I had seen on Vansairforce for solutions. The two key threads are link and link. DanH was the driver behind improving the design for cooling the back cylinder but Mike Robinson was the person who came up with the best solution, a bypass slot that only covers the outside fins of the cylinder.

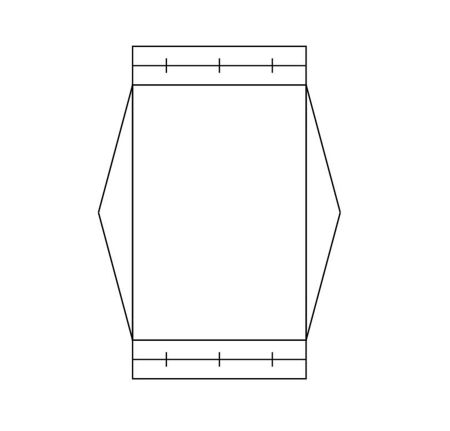

During my build I had gone with the “washer method” that helps by created a gap between the baffle and the cylinder but it leaves a large open area without cooling fins, thus wasting a lot of airflow. Toobuilder posted on Vansairforce, “Calling the washer trick a “solution” is like saying a mini spare on your car is the “solution” to a nail in your full sized tire. It gets you where you want to go, but the car will not perform as designed.” So now it was time to properly address the issue. No dimensions were listed for the bypass area and I chose 1.8″ x 2.65″.

The biggest pain in the ass was picking off all of the old RTV (silicon) that I had originally used to seal the edges of the baffle to the engine block. Woe is me.

UPDATE: Complete success! My test flight showed a 10 degree drop on cylinder 5 and I kept full power (2,700 rpm) throughout the climb with no temperature issues (on the past I would pull back to 2,500 rpm after reaching 500 agl).

No Comments