This week has been constantly interrupted by non-plane building crap. Bunch of real work and two drives to Denver – don’t ask. So progress has been slowed down. Ugh.

One of the slowdowns was getting an oil cooler. I ordered one back in October and ship date after ship date slipped by. Airflow System has a supplier who has had a bunch of excuses concluding on Monday with the batch they built wouldn’t pass QC. Well a week or two from first engine start so I had to pivot. Bill (from Airflow Systems) located a new 2006X and promised that if I had cooling problems he would help me out in the future so that I could upgrade to the 2007X I originally ordered. So for the time being that solved my first engine start/first flight dilemma. I decided to fabricate the 2007X adapter bracket now just in case. With the engine on, if I do decide I need the 2007X, I just have four rivets to drive and cut the opening bigger.

I also fabricated the recommended air vane that goes into the oil cooler bracket and forces even air flow over the top and bottom of the oil cooler. Oil cool/vane riveted it came the fun job of riveting the assembly to the firewall. This took a bit of gymnastics to hold the bucking bar and even a tricky backriveting for two of the rivets. But it turned out great.

The big wait was for the scheduled delivery of my Lycoming Thunderbolt engine. I’ll cut to the chase, at 5:15 I got a call that it somehow wasn’t on the truck…

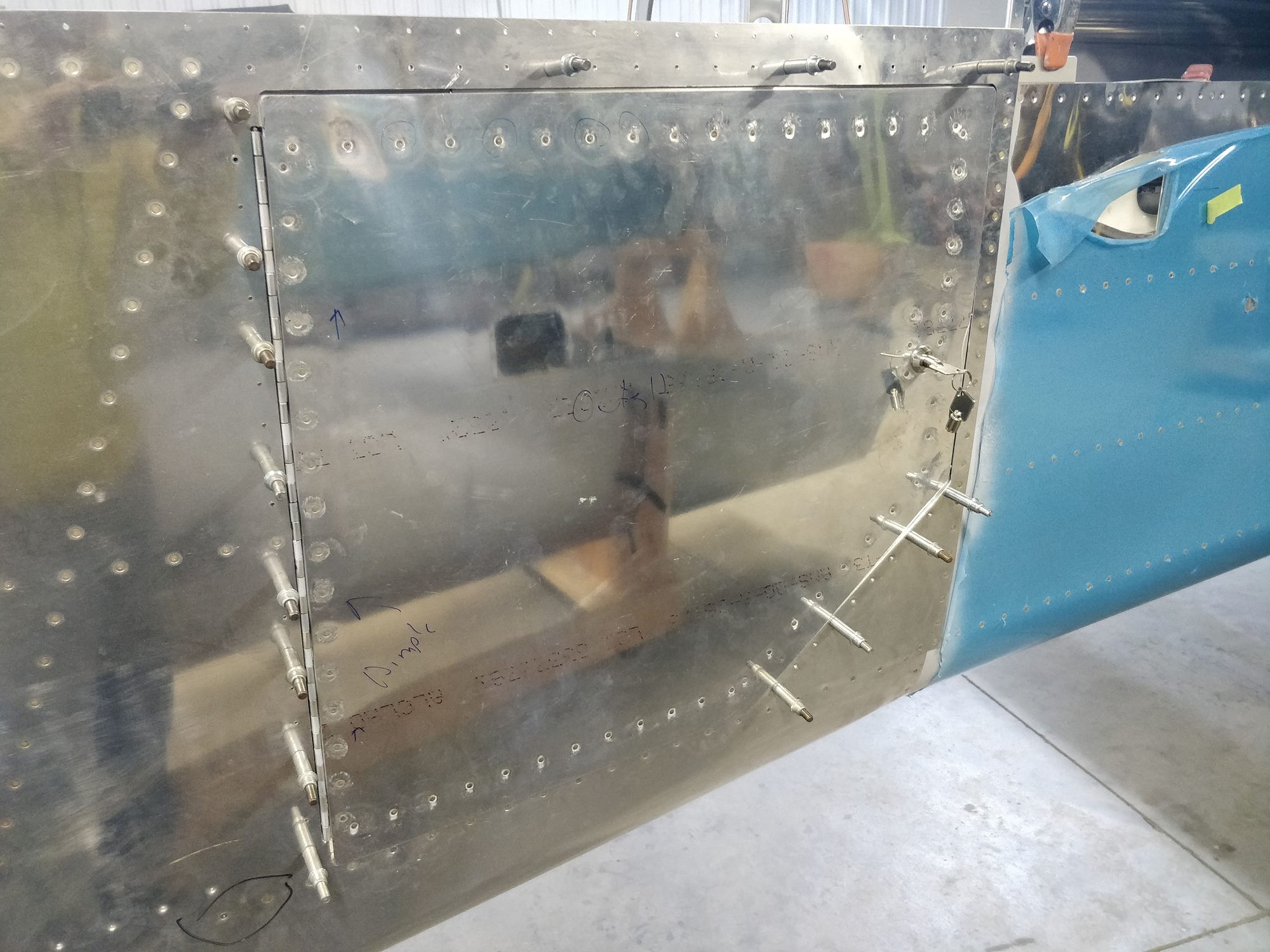

Last project of the day was riveting the baggage door hinge to the airframe and then fabricating the two hinge pins. I went with the hidden removable hinge pin route and it turned out perfect.

No Comments