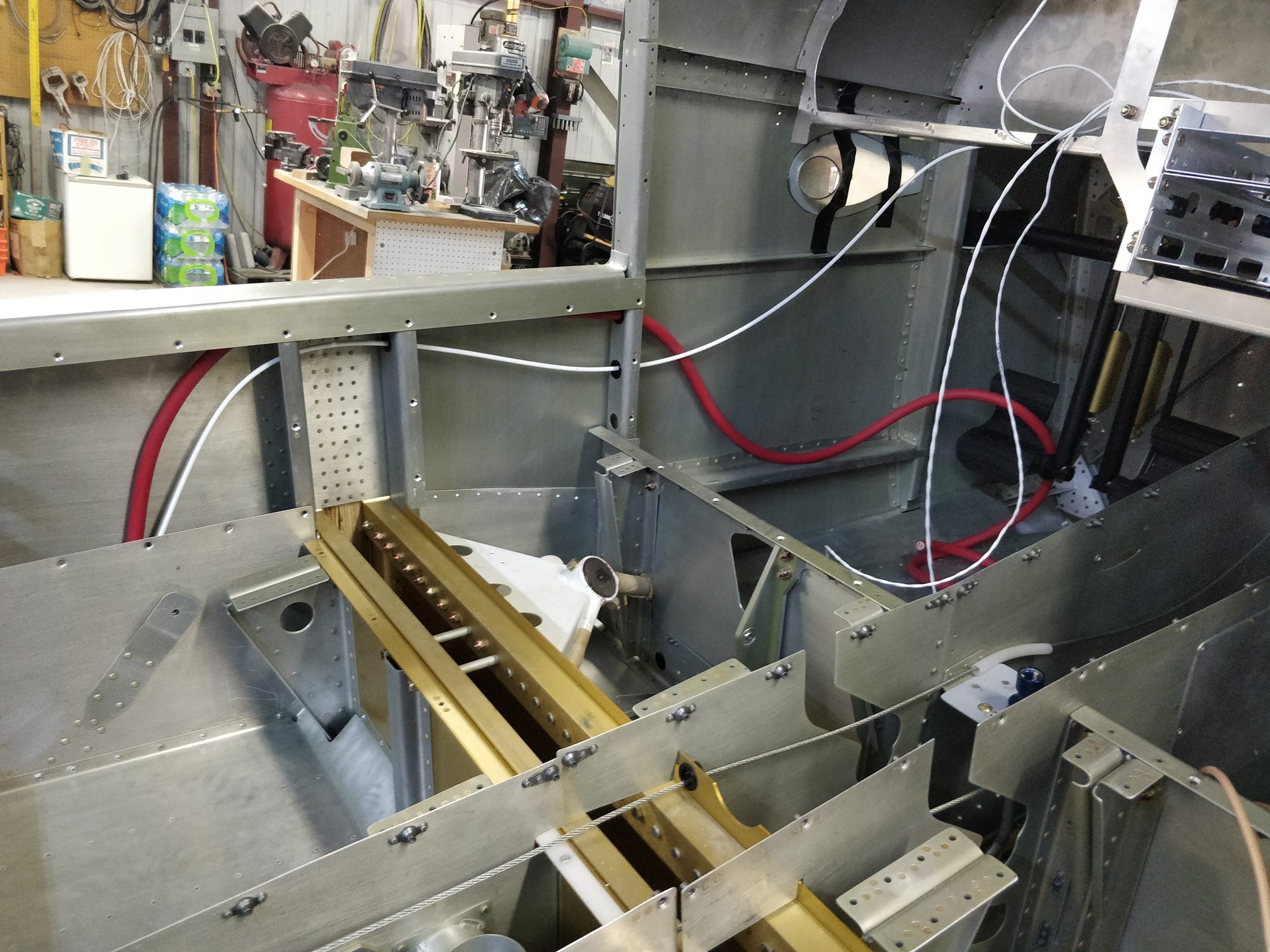

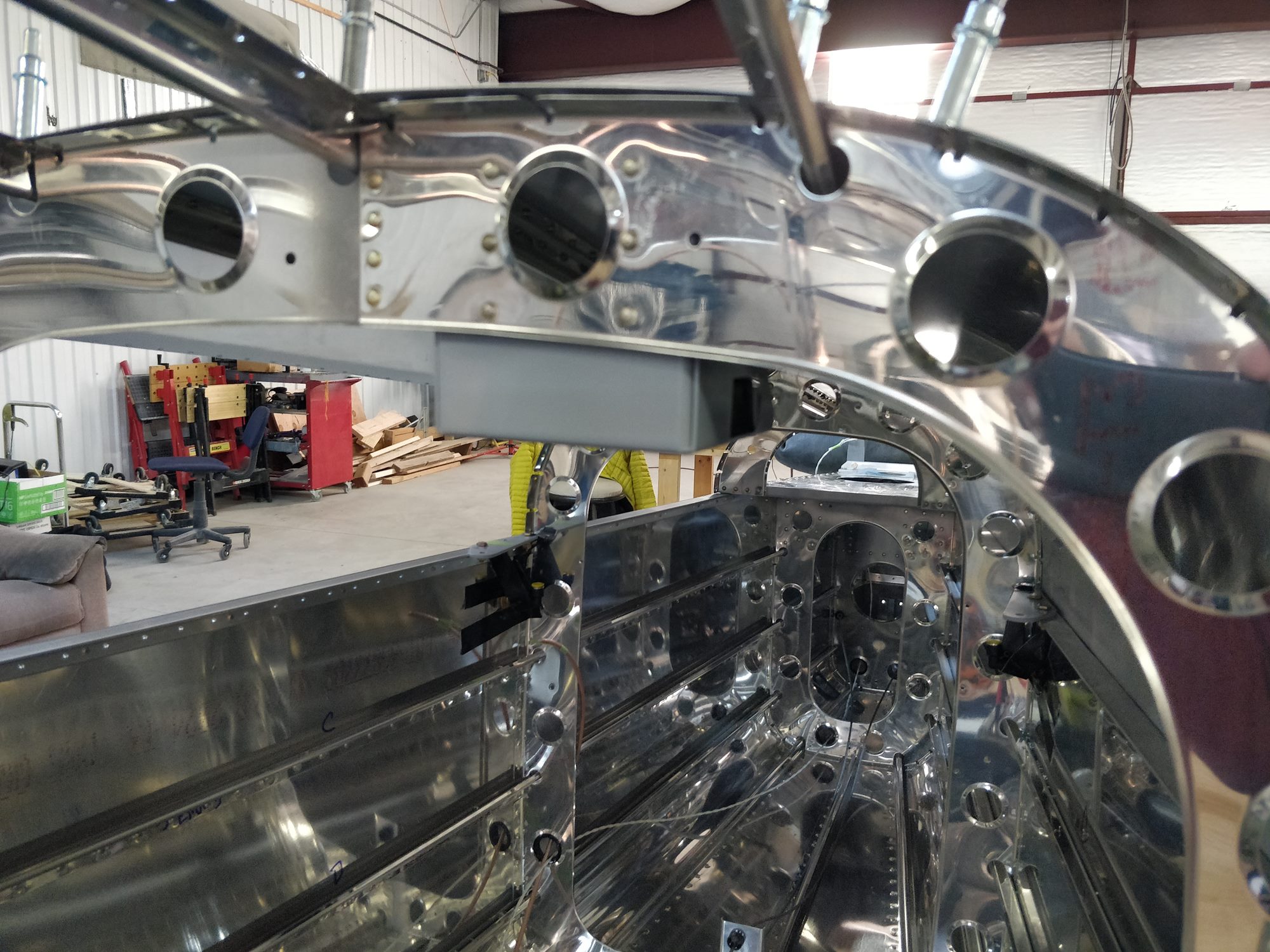

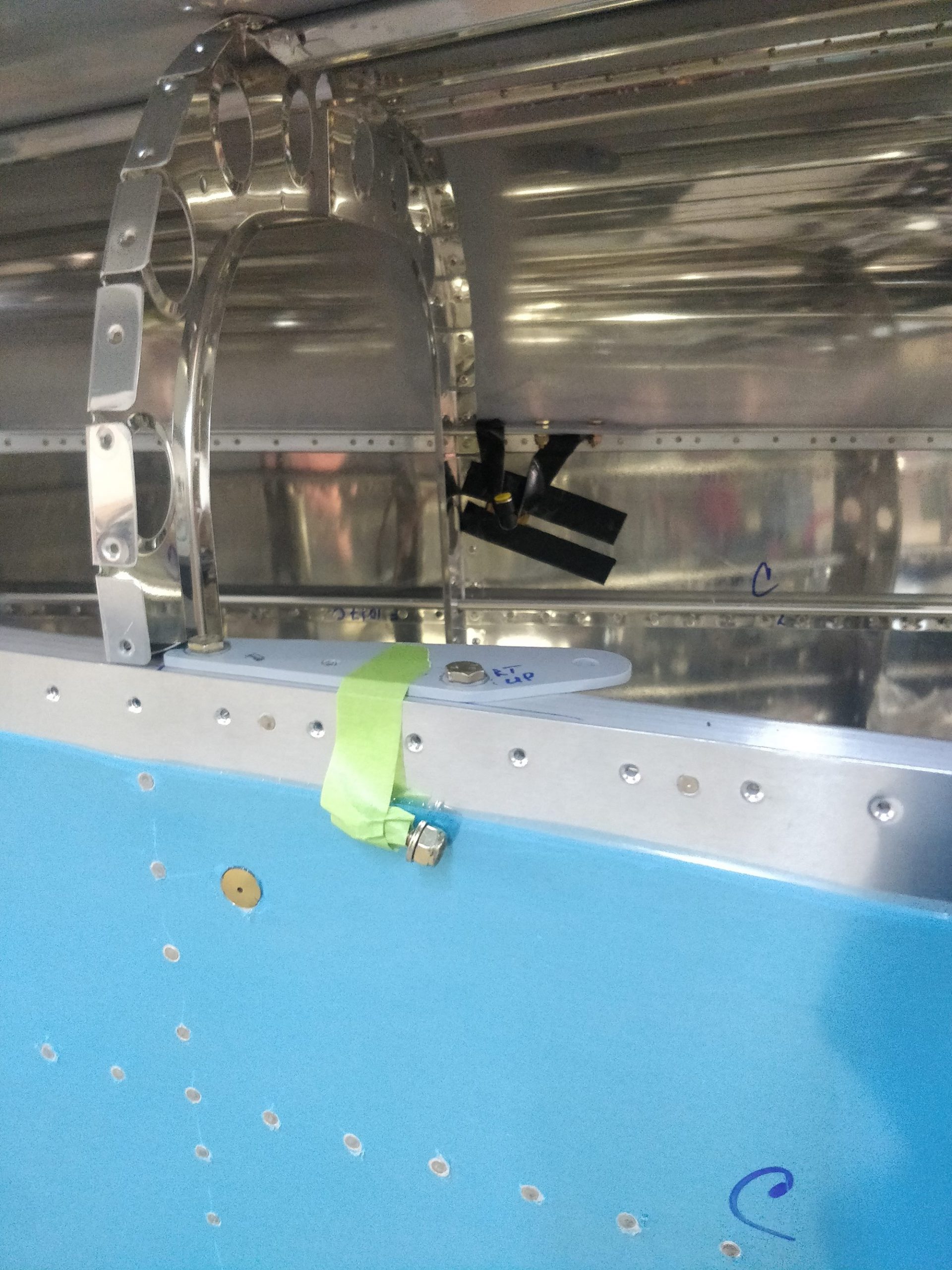

Today was a bit of jumping around. I got a number of the wires pulled through the airframe, mounted the magnometer bracket, got the static ports ProSealed. A big chunk of the day was spent on getting the wheels mounted.

The Matco wheels/brakes was pretty straight forward to figure out the order of installation, wheels on the axles the next step was installing the axle nut and the Matco calls for making the cotter pin holes elongated to lock the axle nut. I didn’t like this idea and a call to a hanger neighbor scored a much more professional installation. Mike has a T-28 he fully restored and a fully equipped machine shop. The threw the axle nuts in his lathe and the conversation commenced while he worked. The result was perfectly machined parts. So great to get help from such a generous guy!

Thinking this day was about wrapped up the axle nuts were installed and torqued, only to find the hydralic fitting was pushed against the wheel pants bracket. Matco tells you this will happen but I just didn’t see it on the bench. Brainstorming commenced and I even pulled in help from another hanger neighbor. Lee came over and recommened bonding a plate to the backside and after the glue cures rivet it to the wheel pants bracket. Then I can grind off the offending area and reassemble the wheels/brakes. What I thought would take a few hours looks like will be an eight hour project. Oh how deviations from plans add up…

No Comments