I fly mostly in the morning and due to living in the mountains it is always cool. However, this summer and fall, I had a number of flights to Las Vegas and on departure it was a lot of work to keep my CHTs below 400 which required a slower climb and reduced power. Not great.

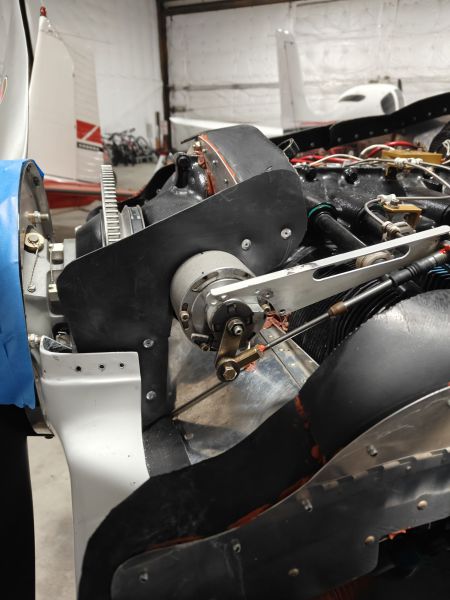

I knew there was poor sealing of the baffles above the prop governor but I was unsure of the best solution. I searched around and didn’t find anything helpful, it seemed most builders with blogs don’t have pictures of that area. I consulted the builders manual (construction drawings) and it was very sparse but there was one photo that I could just make out a small section of baffle material that I had missed when building. This small piece of baffle material did not look large enough to seal the gap and I didn’t want to just throw a random piece of baffle material up there so back to searching.

I stumbled on a blog post by Tim from back in 2006 that was exactly what I needed. Not only did he have great pictures of his baffle in that area but also a long description of other improvements he made; sealing the fiberglass cowling ramps, filling the cylinder heads, and adding additional RTV. Now I had a plan and it was time to get started!

Template with the approximate dimensions (print on paper and fine tune for your installation)” Link

UPDATE 2/15/2025

Duh, during my test flight run-up, after clearing snow for thirty minutes in front of my hanger, I identified an issue with the propellor control. It seems I did not factor in the propellor governor shaft extends as the propellor is moved to low pitch. After some time to recover from my disappointment I pulled the cowl and added a bump out to provide the needed space.

No Comments