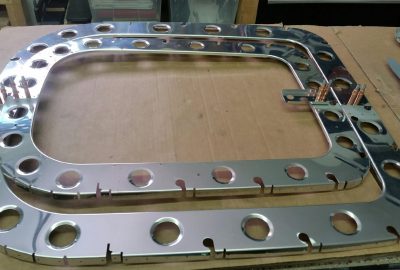

Next up the sides to the Tail!

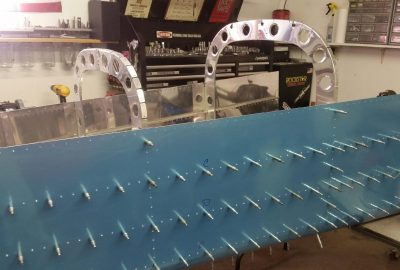

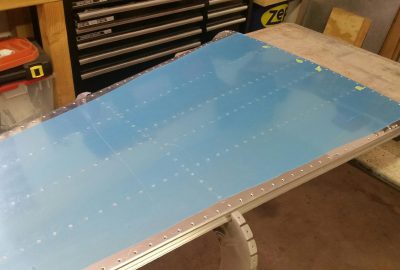

After riveting the belly it was time to move on to the sides. More clecoing of J-channel and figuring out how everything lines up. Fun to see it coming together and looking like something. And nice that all of the rivets are accessible, unlike the Horizontal Stabilizer.