An oil change was due making it a good time to tackle a few projects on N241VP. First up was the oil change, I was one of the lucky few who had stockpiled oil filters (filters have become scarce during the past year). I’m down to my last one but it should get me through until the reusable Challenger oil filter system arrives (ship dates keep getting pushed back again and again so I could still run into issue). Nothing found in the filter and the only drama was my cheap Walmart oil spout popped off getting a few tablespoons of oil dripping down onto the cylinders which required some mineral spirits clean up.

The plugs were coming due (every 125 hours) so I changed them as well. A bit of white on the tips showed them running hot. I talked to Brad at P-Mag and he suggested trying a cooler plug since the timing was spot on and the CHT temps are all good. I’ll probably fly for 10 hours check them and then decided if I should try the cooler plugs.

I had placed tape on the sides of the gear a month ago, as there were signs of slight rubbing on the bottom cowl. Whelp, the rubbing was still there so I opened up the gear leg slot on the bottom cowl, that should take care of that.

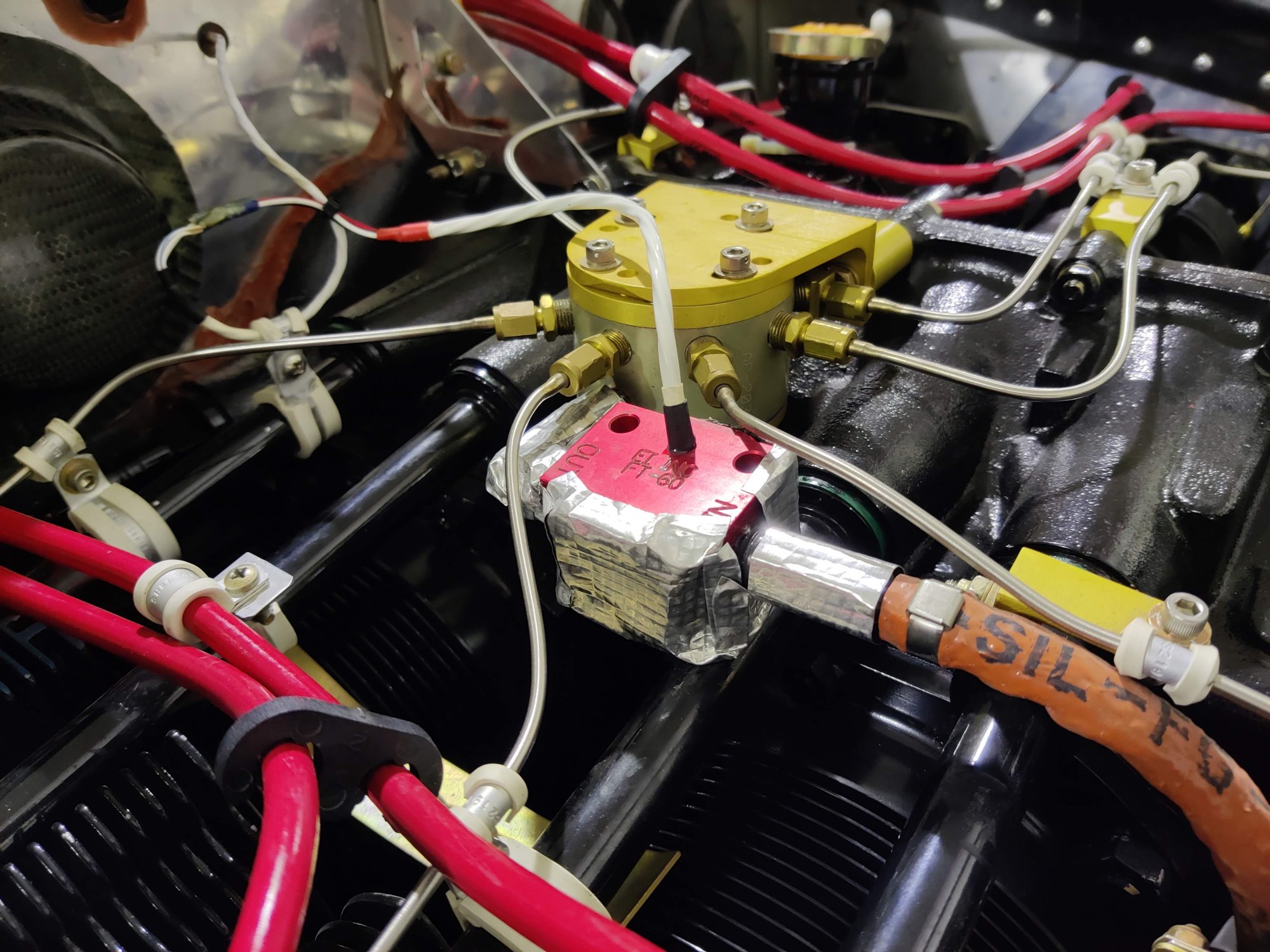

Long taxis in the heat or taxiing following fueling left the engine running rougher, likely due to fuel boiling. Once more fuel runs through the system it is all good but to try and address this I wrapped my red cube fuel flow transducer with Zircoflex heat shield. My first test was a cooler day but didn’t show the engine roughness following a fuel up. More testing to come but it looks promising.

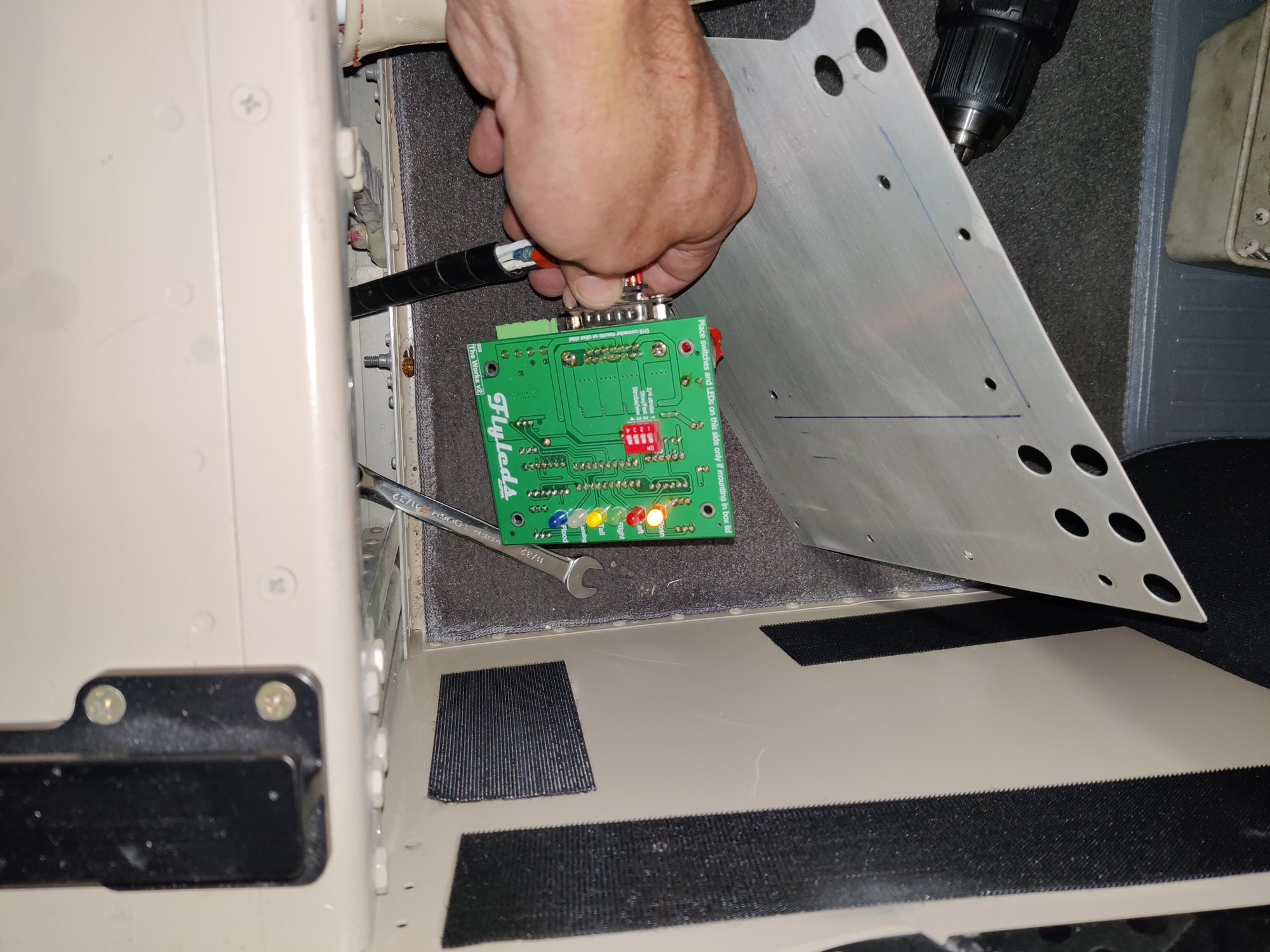

My FlyLED system was finicky at the last condition inspection but it worked. That was until a week ago. So it was time to tear into it. Following advice from Paul at FlyLED I proceeded with some troubleshooting and found that wiggling the connector I could hear arcing and get the strobes to fire. The issue turned out to be a faulty DB-15 connector on the PCB controller. I love the FlyLED system but I scratch my head at the cheap DB-15 connectors they provide. Back before my Airworthiness Inspection I had to scramble after the cheap pressed pins on the cable DB-15 connector broke. I have now switched out the DB-15 connectors for both the cable and PCB with high quality machined pins so future problems should now be eliminated.

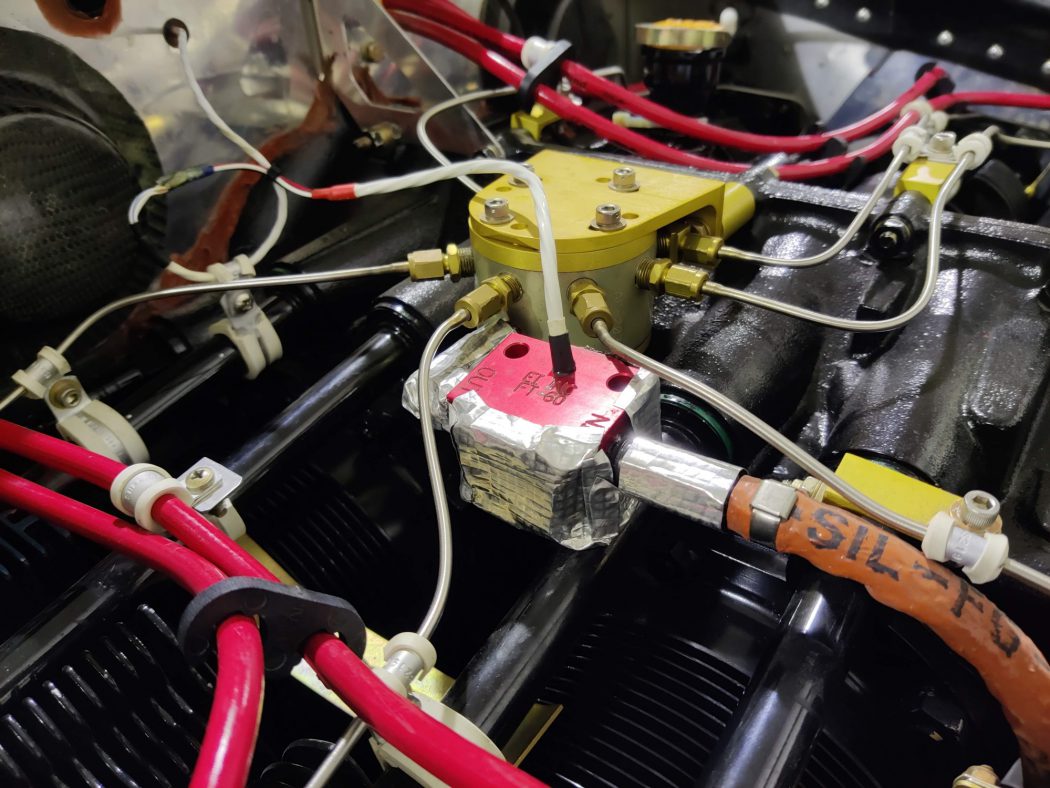

My Savvy advisor recommended adding a snubber to my Manifold Pressure sensor after seeing some fluctuations in flight. Evidently Garmin has added a snubber to new sensors but I was left adding an external one. Scott McDaniels (Van’s prototype manager), mentioned on VAF that the standard 0.040″ snubber wasn’t sufficient for the Van’s RV-10 demo plane. I sought the advice from the RV-10 Facebook group and found wide ranges from 0.004″ to 0.015″ including someone who made a manifold to connect the MAP sensor to three cylinders. I ended up drilling the adapter to 0.020″. After three short flights it seems to be doing the trick and will have less potential to clog up (one comment on FB mentioned periodic cleaning of the tiny hole).

Cleaned the engine compartment and did a thorough inspection checking for rubbing of anything in the engine compartment.

No Comments